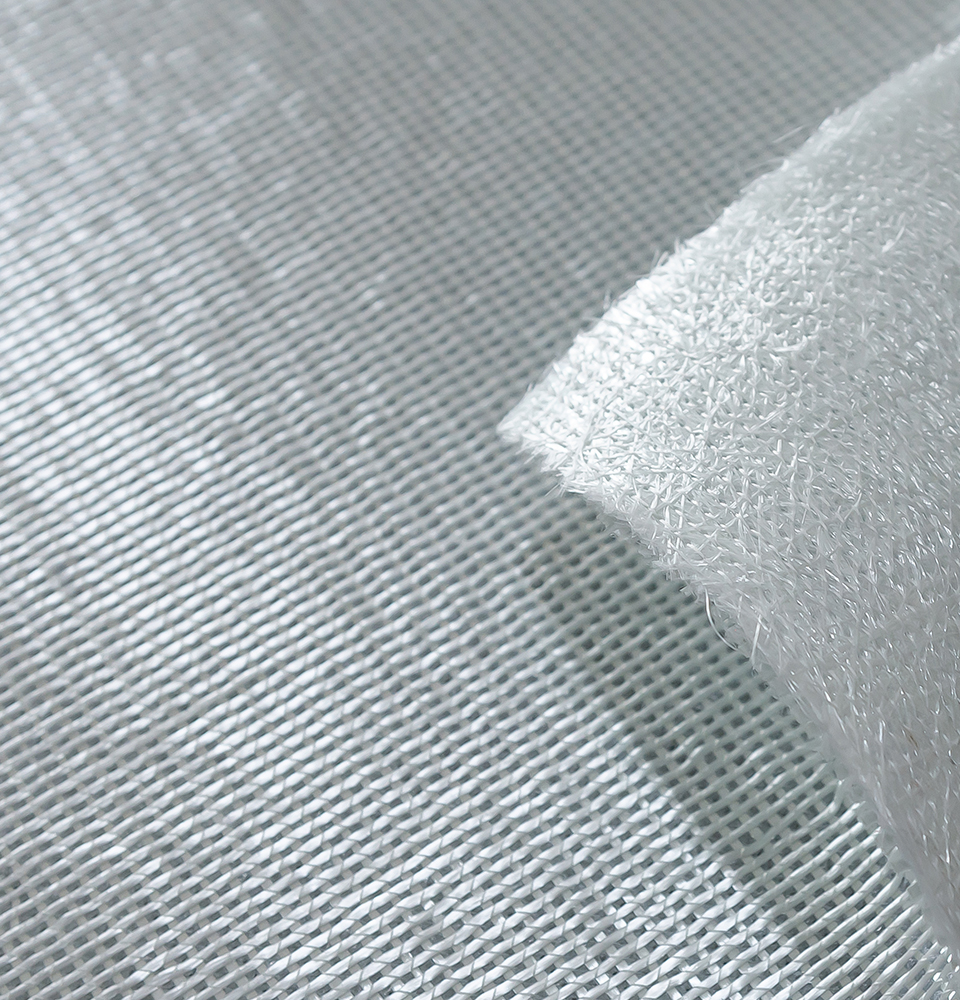

Fiberglass Sandwich Core Materials are advanced composite reinforcements engineered with a synthetic non-woven core laminated between layers of fiberglass fabrics—such as chopped strand mat, multiaxial fabric, or woven roving. This layered structure ensures excellent resin flow, consistent thickness, and superior mechanical strength during closed mold processes like RTM, vacuum forming, injection molding, and SRIM.

Swipe or wait — images change automatically.

| Specification | Total weight (gsm) | Deviation(%) | CSM(gsm) | Core(gsm) | CSM(gsm) | Stitching Yarn(gsm) |

| CF150/130/150 | 440 | ±7 | 150 | 130 | 150 | 10 |

| CF300/180/300 | 790 | ±7 | 300 | 180 | 300 | 10 |

| CF450/180/450 | 1090 | ±7 | 450 | 180 | 450 | 10 |

| CF600/250/600 | 1460 | ±7 | 600 | 250 | 600 | 10 |

| CF1100/200/1100 | 2410 | ±7 | 1100 | 200 | 1100 | 10 |

| Specification | Total weight (gsm) | Deviation(%) | 0°Degree(gsm) | 90°Degree(gsm) | Core(gsm) | CSM(gsm) | Stitching Yarn(gsm) |

| LTNM600/180/300 | 1090 | ±7 | 336 | 264 | 180 | 300 | 10 |

| LTNM600/180/600 | 1390 | ±7 | 336 | 264 | 180 | 600 | 10 |

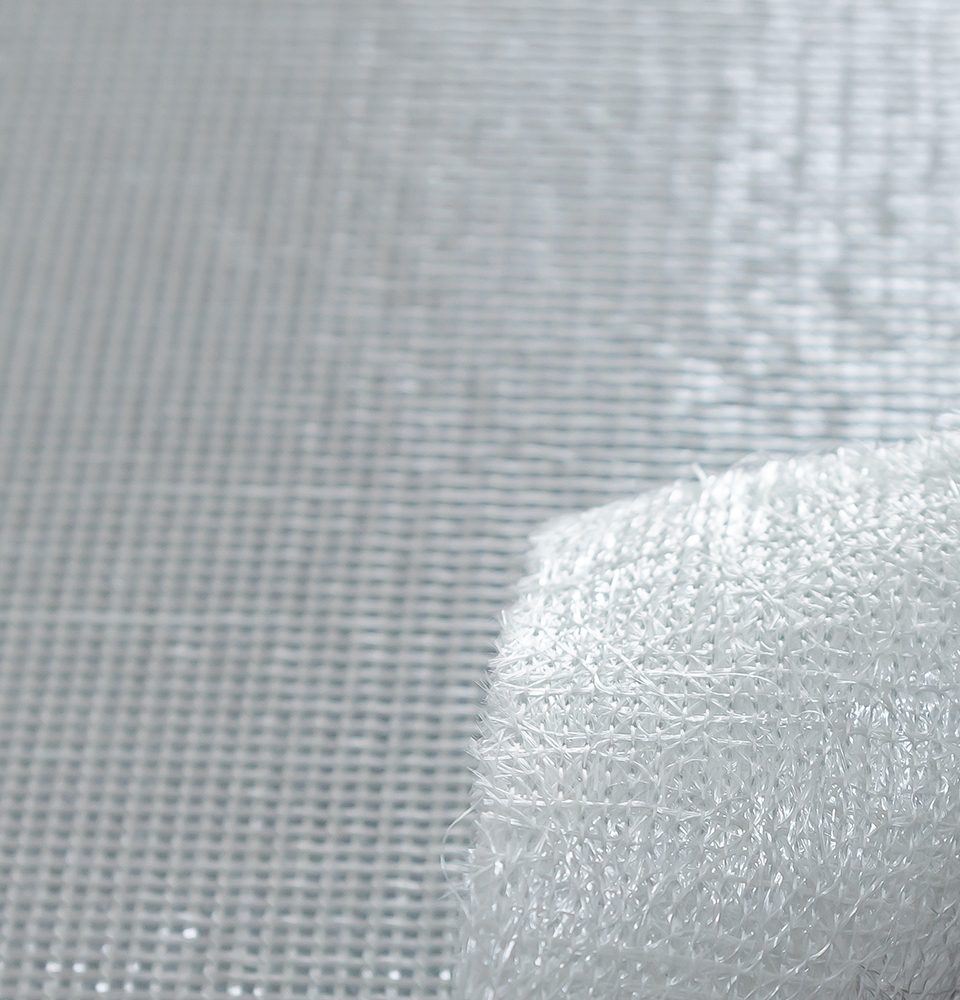

Here we mainly have 2 kinds of fiberglass sandwich core materials, Closed Mold Mat CF and Flow Medium LTNM.

Closed Mold Mat CF is a glass fiber surface reinforcement material designed specifically for closed mold processes (such as RTM, LRTM, infusion, etc.). It is commonly used in sandwich structures between the gel coat layer and the core material to improve surface quality and enhance structural strength.

▪ Excellent conformability: Can be smoothly spread over complex mold surfaces, reducing operational difficulty and dry spots.

▪ Improved surface quality: Effectively reduces “print-through” issues, forming a resin-rich and smooth surface layer.

▪ Fast wetting performance: Good resin permeability, accelerating the molding cycle.

▪ Strong compatibility with closed-mold molding: Moderate permeability ensures good compatibility with RTM-type processes.

As you can see, we offer customized CF products in a variety of weights, thicknesses, and permeability grades, compatible with multiple resin systems (epoxy resin, vinyl ester resin, unsaturated polyester, etc.). Each batch of products undergoes strict formulation control and consistency testing to ensure stable final component quality and a smooth surface finish. We also provide composite layup structure recommendations to support efficient closed-mold production.

Flow Medium LTNM is a lightweight, high-efficiency flow medium used in closed-mold processes. Its main functions are to guide the uniform flow of resin, accelerate wetting speed, optimize resin flow paths, and ensure complete impregnation and curing quality in complex structures.

▪ High permeability, rapid flow: Significantly accelerates resin flow speed and shortens mold filling time.

▪ Easy to lay and cut: Flexible, suitable for molds of various complex shapes.

▪ Precise thickness control: Low thickness design avoids fluctuations in structural layer thickness that affect the accuracy of the finished product.

▪ Compatible with multiple resins: Can be used with multiple resin systems such as epoxy, polyester, and vinyl ester.

We have extensive experience in developing fluid media, and our LTNM products can be customized to meet specific requirements in terms of weight, thickness, and flow rate. Our engineering team can assist customers in evaluating infusion pathways, optimizing layup schemes, and recommending suitable combinations of flow control materials based on specific applications to achieve higher molding efficiency and reduce residual stress.

One roll is wrapped in plastic film and then placed into a carton or a large carton.

Normally, P4 (4 big rolls) or P7 (4 big rolls + 3 small rolls) or 6, 9, or 12 small rolls are packed per pallet horizontally/vertically. It can be customized based on the loading method.

Fiberglass products should be stocked in a dry, cool, and waterproof place. The best condition is with a temperature between 15-35℃, with a relative humidity between 30%-65%. Please keep the product in its original packaging before use, avoiding moisture.

Weitong currently operates over 30 fiberglass weaving machines for producing woven roving, along with various other equipment, including stitched mat machines, multiaxial tricot machines, PP core mat machines, and carding machines. Our annual production capacity reaches 3,000 tons of woven roving, 5,000 tons of stitched mat, 10,000 tons of multiaxial fabrics, 8,000 tons of combo mat, and 2,000 tons of RTM core mat.

Our team has already attended the China(Shanghai) International Composite Exhibition for 9 years, and JEC France, Composites Europe, and JEC Asia several times in France, Germany and Korea.

Backed by a highly skilled team of professional technicians, we have strong capabilities in developing and customizing specialized products to meet diverse customer requirements.