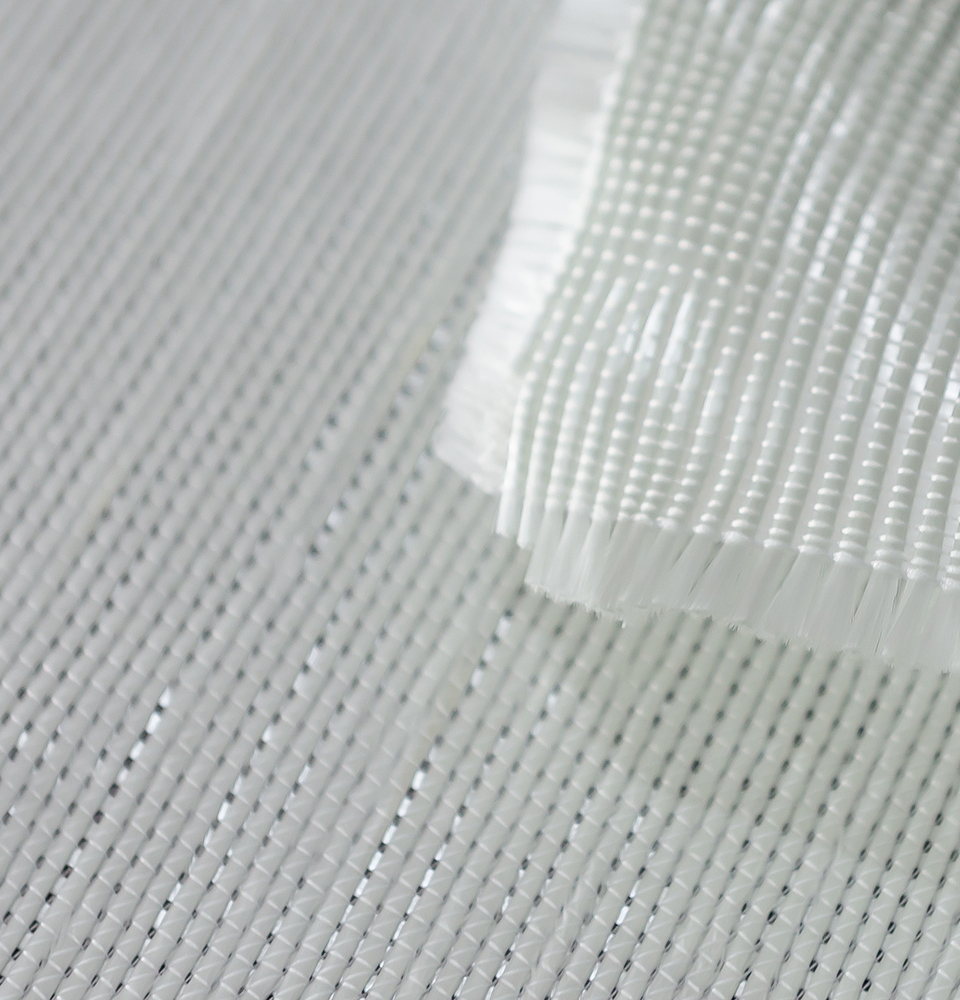

Fiberglass Multiaxial Fabric Cloth is a high-performance series of stitched reinforcements engineered for advanced composite applications. These fabrics are composed of multiple layers of fiberglass oriented in specific directions and stitched together without binder, ensuring excellent drapability, mechanical strength, and consistent resin flow.

Swipe or wait — images change automatically.

| Specification | Total weight (gsm) | 45°Degree(gsm) | -45°Degree(gsm) | CSM(gsm) | Stitching Yarn(gsm) |

| BXM600/225 | 832 | 300 | 300 | 225 | 7 |

| Specification | Total weight (gsm) | Deviation (%) | 0° degree (gsm) | 90° degree (gsm) | Stitched Yarn (gsm) |

| LT600 | 610 | ±7 | 336 | 264 | 10 |

| LT800 | 810 | ±7 | 336 | 464 | 10 |

| LT600 | 610 | ±7 | 420 | 180 | 10 |

| LT800 | 810 | ±7 | 420 | 380 | 10 |

| LT1000 | 1110 | ±7 | 672 | 328 | 10 |

| LT1200 | 1510 | ±7 | 672 | 528 | 10 |

| Specification | Total weight (gsm) | 0°Degree(gsm) | 90°Degree(gsm) | CSM(gsm) | Stitching Yarn(gsm) |

| LTM600/300 | 910 | 336 | 264 | 300 | 10 |

| LTM800/300 | 1110 | 420 | 380 | 300 | 10 |

| LTM1200/300 | 1510 | 672 | 528 | 300 | 10 |

| Specification | Total weight (gsm) | 90°Degree(gsm) | CSM(gsm) | Stitching Yarn(gsm) |

| UDTM200/225 | 435 | 200 | 225 | 10 |

Fiberglass Multiaxial Fabric Cloth is a high-performance reinforcement material composed of multiple layers of fiberglass yarns aligned in different orientations such as ±45°, 0°, and 90°. Compared to traditional woven fabrics, multiaxial fabrics provide better load distribution, superior mechanical strength, and reduced resin consumption, making them ideal for structural composites.

We offer a wide selection of multiaxial fiberglass fabrics:

±45° BX (Biaxial): Offers excellent shear strength and is often used in applications requiring torsional rigidity, such as wind blades and automotive components.

0°, 90° LT (Layered Triaxial): Designed for balanced reinforcement in both warp and weft directions, ideal for panels and shells requiring in-plane strength.

0°, 90° Add Mat LTM: Incorporates chopped strand mat for improved isotropic properties and enhanced resin flow in molding processes.

Unidirectional UDTM: All fibers aligned in a single direction, maximizing tensile strength along that axis, commonly used in aerospace, marine spars, and wind turbine beams.

We offer full technical support, including:

▪ Custom lay-up configurations

▪ Pre-cut kits and roll packaging

▪ Fabric performance simulation

▪ Resin compatibility consulting

One roll is wrapped in plastic film and then placed into a carton or a large carton.

Normally, P4 (4 big rolls) or P7 (4 big rolls + 3 small rolls) or 6, 9, or 12 small rolls are packed per pallet horizontally/vertically. It can be customized based on the loading method.

Fiberglass products should be stocked in a dry, cool, and waterproof place. The best condition is with a temperature between 15-35℃, with a relative humidity between 30%-65%. Please keep the product in its original packaging before use, avoiding moisture.

Weitong currently operates over 30 fiberglass weaving machines for producing woven roving, along with various other equipment, including stitched mat machines, multiaxial tricot machines, PP core mat machines, and carding machines. Our annual production capacity reaches 3,000 tons of woven roving, 5,000 tons of stitched mat, 10,000 tons of multiaxial fabrics, 8,000 tons of combo mat, and 2,000 tons of RTM core mat.

Our team has already attended the China(Shanghai) International Composite Exhibition for 9 years, and JEC France, Composites Europe, and JEC Asia several times in France, Germany and Korea.

Backed by a highly skilled team of professional technicians, we have strong capabilities in developing and customizing specialized products to meet diverse customer requirements.