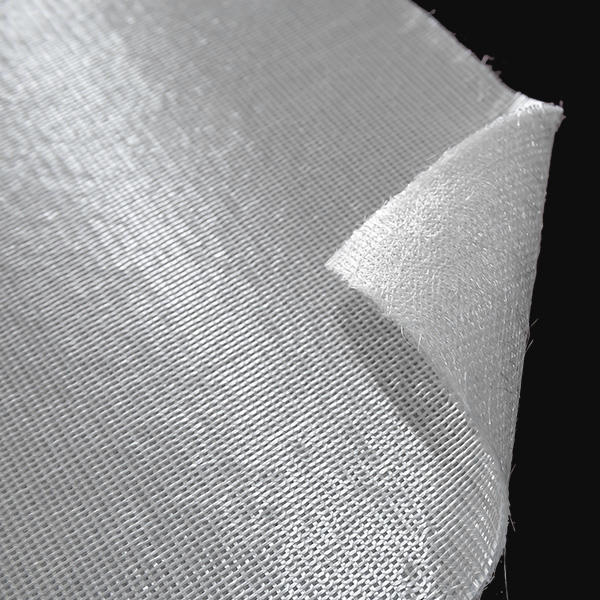

Fiberglass core mats are made of high-density polyethylene plastic and are designed to stand up against heavy pressure. These mats are used for different applications such as marine applications and come in many different color options and materials. The fiberglass is formulated with an epoxy resin that bonds with any type of fiber or laminate. The fibers can be connected to form an incredibly durable and strong material.

The fiberglass is available in both closed cell and open cell mats. In general, the closed cell type has a thicker core and can absorb more moisture. The open cell can have less density and is designed to provide a more flexible surface for a given application. Many businesses prefer the use of fiberglass mats over concrete because they are slip resistant and also offer a greater level of puncture resistance than most synthetic alternatives.

Weitong Fiberglass mats are produced with a wide variety of fillers, including silicon carbide and aluminum oxide. These additives make the mats more flexible and increase their structural integrity. Typically, fiberglass matted are custom designed by a skilled manufacturer and engineer. When purchased from a good manufacturer, the result will be a product with excellent craftsmanship and design. The manufacturer will work closely with you to develop the appropriate specifications for your particular job site. Once you have decided on the right mat, the company will begin the production process.

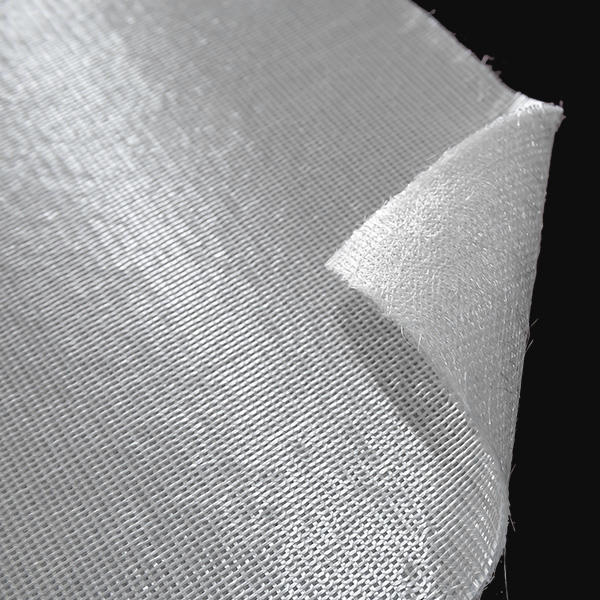

Once your order has been confirmed, the manufacturer will place your order with matted sheets or rolls, and then bring the fiberglass to your location for installation. The fiberglass matting can be cut to fit the specific area with a hand saw, but it may require some careful cutting. The matted sheets or rolls can be placed on top of the existing surface, or they can be secured directly to the ground.

Once the matted sheets or rolls are on the site, the technician will begin installation. Usually, a padlock is used to secure the fiberglass mat to the surface, and then the technician will place the foam core over the matted sheeting. This creates an extra layer of insulation between the floor and the matted sheets, which help to reduce moisture transfer and heat transfer.

When installing the foam core, the technician will use a spray bottle to apply the adhesive. This will coat the fiberglass sheets and create a water seal around the edges of the mat. Once this step is completed, the matted sheets are laid out to be cut to size. Usually, the technicians will cut the matted sheets in half, but if time is an issue, they can also cut the mat into quarters.

When cutting the matted sheets to size, no slippage should take place. The mat should be laid directly on the pad, with the matted sheet on top. This will ensure a tight fit and prevent water from seeping underneath. Once cut to size, the mat should be laid flat on the ground, and the sheet should be laid across the entire mat. When complete, the sheet should be secured with a spray cap, and any extra water should be captured with a drop cloth.

With the fiberglass mat installed, the technician will want to inspect it for damage. If any slippage should occur, it should be immediately replaced by the technician. This will ensure that the floor will be safe and free of water for many years to come.

With fiberglass mats, there is the possibility of a rare issue that is common with fiberglass. While extremely rare, if it does occur, it is easily corrected. If water gets into the fiberglass mat, the solution is simple - get some flooring spray. This will eliminate the water and make the repair easy.

Matted flooring is a solid and durable alternative to the traditional vinyl flooring found in most homes. It is available in many different sizes and can cut costs and labor in half when used as a base under existing floors. If you are looking to install a new floor at your home, matted sheets may just be the answer you have been looking for.

Replacing an older floor can be a difficult task. Many older houses do not have the proper drainage systems in place, which makes removing and installing the subfloor a more difficult process. When using a matted fiberglass sheet as a base, the floor will be protected from any moisture that can occur from below. The matting also protects the floor from damage caused by continued water, which can cause buckling or even complete failure.