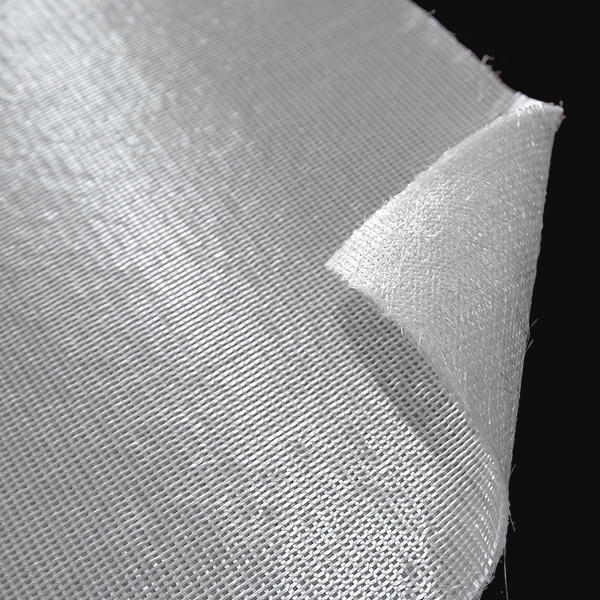

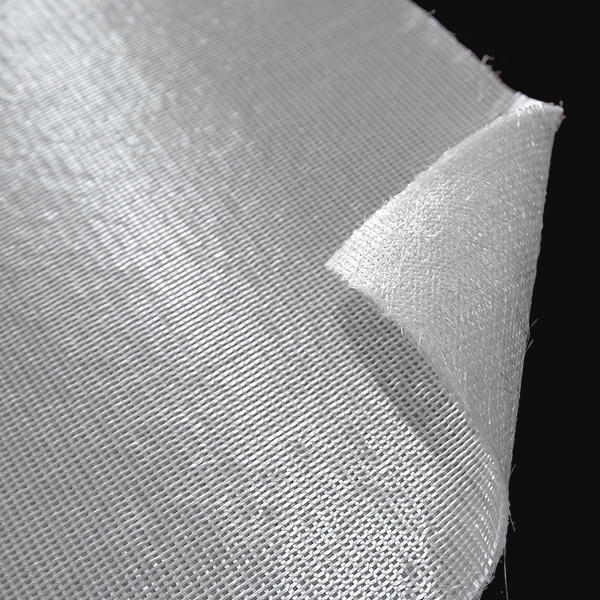

Abstract:A Fiberglass Core Mat is a synthetic non-woven fabric sandwiched between two layers of a multiaxial fabric. Its high-quality structure retionality mak

A Fiberglass Core Mat is a synthetic non-woven fabric sandwiched between two layers of a multiaxial fabric. Its high-quality structure retionality makes it a popular choice for marine applications and recreational vehicles. This product dries quickly and conforms to the contours of a mold. The advantages of this product are clear: it is highly durable, provides a high level of flexibility and offers excellent flexibility.

The material is made from a polyester non-woven fabric. It serves as a thin core in composite materials and a print blocker. It can be applied to all types of composite parts, including hatch covers, steering consoles, and shower cabinets. It also serves as an interlaminar infusion medium and as a print barrier in hull sides. It is easy to apply, and is very strong. It is also a cost-effective choice for many applications.

Its high-quality non-woven fabric is a cost-effective, high-quality core material for composite constructions. Its unique properties make it a popular choice for marine applications. Its durability, and cost-effectiveness make it an ideal choice for boat constructions. It can also be used as a print-blocker in FRP products. The non-woven fabric is typically 2mm to 3mm thick and is a versatile solution for a variety of applications.

When it comes to the quality of Fiberglass Core Mat, its thickness and rigidity are important factors. It is usually 2mm to 3mm thick. It can be trimmed to the desired thickness for the product. This reduces product cost and build time, and it provides the rigidity necessary for marine structures. Additionally, Coremat is a cost-effective option for boating applications. And unlike other types of composites, it can be molded into a variety of shapes and sizes, saving the company a lot of money.

Fiberglass Coremat is a nonwoven fabric that forms an integral part of the finished product. Its color and pattern won't delaminate, and it provides stiffness and rigidity. In addition to reducing product costs, Fiberglass Core Mat can help speed up production. This means it will take less time to build the composite part. It also increases the structural strength of the product. It will be a strong and sturdy piece of boating equipment.

A nonwoven fabric, Coremat is a lightweight, flexible core for composite parts. It is a key component in many composites, including boating, airplanes, and other structures. It is a good choice for boating applications, as it can reduce the build time and product cost. In fact, it is also an excellent choice for FRP products. This material is used in many types of marine environments, including in the construction of boats.