Abstract:A biaxial fabric has two layers stitched together with fiber strands arranged 45 degrees from the edge. In comparison, plain weave fiberglass fabrics

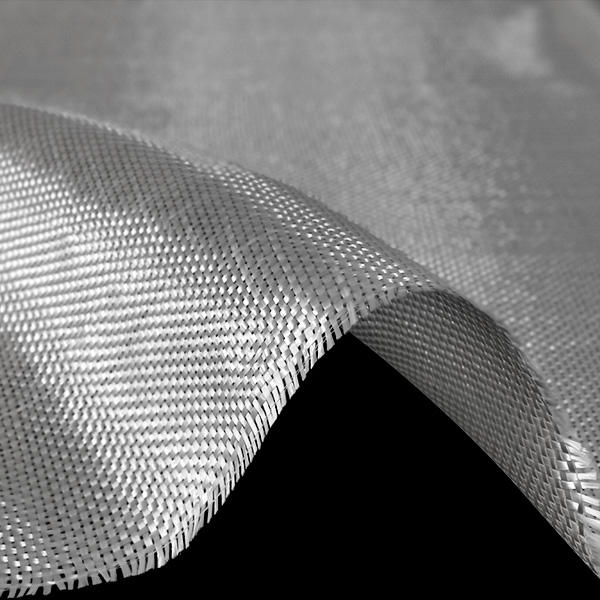

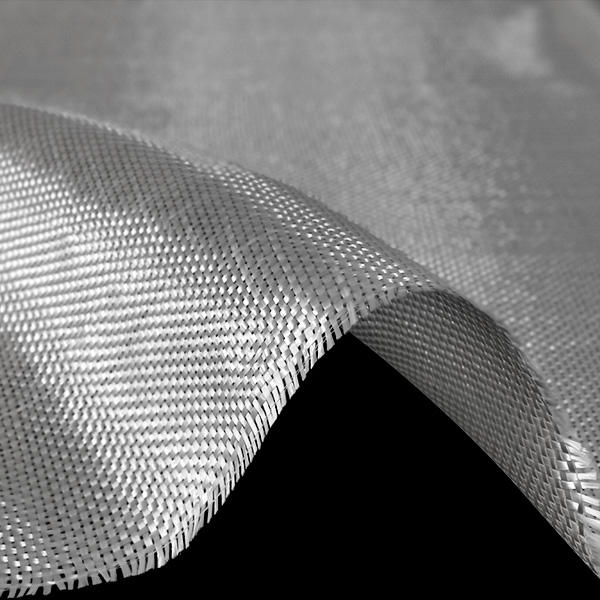

A biaxial fabric has two layers stitched together with fiber strands arranged 45 degrees from the edge. In comparison, plain weave fiberglass fabrics have fiber strands that are 90 degrees from the edge. This material is available in 18 oz. and 17 oz. woven varieties and is sold by the yard. All biaxial fabrics are backed with a 3/4 oz. mat to provide extra thickness.

The strength of fiberglass is dependent on the direction in which the fibers are oriented. This makes nonwoven fiberglass fabric a superior choice for complex FRP/Composites. This type of fabric also dries more quickly than woven materials. It is also more efficient at reinforcing, tabbing, and repair jobs. It is stronger than cloth, but it is less smooth. It soaks up a great deal of resin and is less smooth than woven fabric.

Fiberglass Biaxial Fabric is a type of non-woven fiberglass fabric that has two or more layers. The fibers are oriented in a 45-degree direction, which allows the fiber to lay in any direction. This biaxial fabric is able to conform to any shape and offers reduced print-through. The increased stiffness of this material makes it an excellent choice for structural composites. A biaxial fabric with mat backing also adds thickness to the fabric and is useful for tabbing and reinforcing.

Fiberglass Biaxial Fabric is a material composed of two or more layers of fiberglass roving. The biaxial material is generally used for complex FRP/Composites, including marine structures. This material is highly durable and is suitable for many applications. It can also be used as an inner layer of glass fibers in composites. In addition to biaxial fabrics, triaxial fibers are more commonly used in boat building and shipbuilding.

Fiberglass biaxial fabric is a non-woven material that is made from two or more layers of roving fiberglass. This type of fiber is oriented at a 45-degree angle, and is stitched with polyester yarn. Because of the biaxial orientation, it is easy to form, and has a smooth finish. For these reasons, it is widely used in boats, aircraft, and other structures. But if you're looking for an ideal material, this is it!

A biaxial fiberglass fabric is made of E-glass roving that is oriented at 45 degrees. The fibers can be arranged in any way, and the fabric can conform to any shape. This type of fabric is also more rigid than woven fabrics. Compared to a woven fabric, it is much more difficult to print through it, and it is less likely to crease. It also tends to be easier to work with than a woven fabric.

Another advantage of biaxial fabric is its ability to absorb resin. Its ability to absorb resin is beneficial in large projects and is useful for surface strengthening. Its small weight also makes it ideal for boats. For this reason, it is widely used in the construction industry. However, a biaxial fabric can be more expensive than woven fabric. A typical fibreglass roving consists of two parallel strands of fibres.