Abstract:Fiberglass woven roving masts are used in the construction of the vast majority of recreational vehicles today. The popularity of these types of rving

Fiberglass woven roving masts are used in the construction of the vast majority of recreational vehicles today. The popularity of these types of rving systems is based upon their ability to withstand a wide variety of driving conditions and climates. They also provide added strength to trailers, in the form of sidewalls and cross boards. The materials have been tested for tensile strength and the best manufacturers of these systems are Flex-It, Strick, and Twin Engine. These manufacturers have continually improved their products for the needs of consumers.

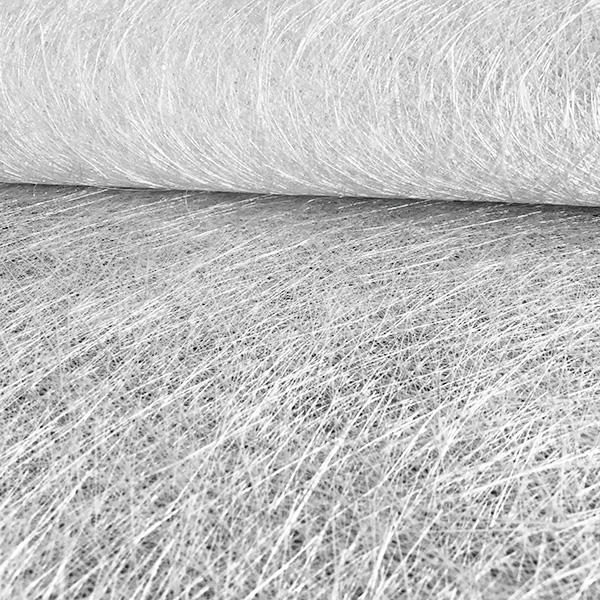

The fiberglass woven roving, plain weave, for recreational vehicle repairs of car, boat, truck, pools, decks,crafts etc. is suitable for use with many epoxy, resin, polyester, and vinyl ester systems. This type of repairing material has a much higher R-value (rate of load-bearing) than that of other fiberglass blends. It also consists of smaller particles which provide increased strength and reduced penetration, due to its small internal diameter. It's low vapor transmission and high compressive strength allows it to have a relatively low temperature rise per square inch.

This type of fiberglass woven roving fiber is more difficult to manufacture than other similar fabrics. The raw materials required to manufacture this fiberglass are primarily hard plastic and carbon. The manufacturing process is achieved by spinning at very high speeds in low pressure, which helps to create large voids in the fabric. The void areas are called sags, and once enough material has been spun into the required areas, the material is then cured in low pressure, using a chemical solvent. This curing process produces a larger surface area for the resin, as well as providing greater strength and dimensional stability to the finished product.

This type of fiberglass woven roving is usually blended with another resin, such as vinyl ester or polyester to produce a single-product, highly conductive material, such as PVC. This material is then used to manufacture the final component. There are some disadvantages of using fiberglass woven roving as a component in a marine application. Because the component uses vinyl esters for its conductivity, some of the flexibility of the marine grade part is lost when the component is exposed to salt water, making this type of fabric less seaworthy than some other marine fabrics which do not contain vinyl esters.

This fabric may be mixed with plain weave resins for low cost, high conductivity, and greater ability to adhere to an acrylic coating. This method is often used as an alternative to thermoplastic mixes (which are low-density liquid resins), especially when mixing solid state plastics with resins. Since the component is mixed with the resin before manufacture, it is guaranteed that there will be no contamination between the two systems after they are blended together. Many marine applications do not need to use pure silicone (or other thermoplastic resins) since the mixed components provide the same conductivity properties.

If you are looking to get the best value out of your investment, go ahead and get the best performance out of your boat by checking out a high performance fiberglass roving mat at Lowes. The company is known for providing quality boat parts at a great value. You can go online and check out Lowes coupons and get the best possible price on your gsm fiberglass woven roving mat. You can also get free shipping if you take a quick look around online.