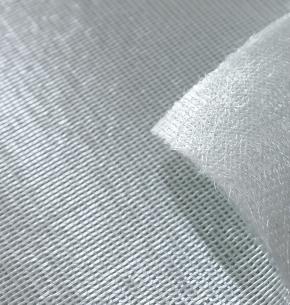

Fiberglass Core Mat is a new material comprising a synthetic non-woven core, sandwiched between 2 layers of chopped glass fibers or one layer of chopped glass fibers and the other layer of multiaxial fabric/woven roving. Mainly used for RTM, vacuum forming, molding, injection molding, and SRM molding process, applied to FRP boats, automobiles, aeroplanes, panels, etc.

1. Sandwich construction can increase the strength and thickness of the product

2. High permeability of the synthetic core, good wet-out in resins, fast solidifying speed

3. High mechanical performance, easy to operate

4. Easy to form angles and more complex shapes

5. Core resilience and compressibility, to adapt to the different thickness of parts

6. Lack of chemical binder for a good impregnation of the reinforcement

If you have any questions, require additional information, or would like to contact our team, we are here to assist you.

Email: info@wtfiberglass.com

Phone: +86-573-88687898 / +86-18610855617

Address: No.168 Jianye Road, Fengming Street, Tongxiang, Zhejiang, China,314505

Website: https://www.wtfiberglass.com/

Should you have any questions regarding our products, production methods, or market insights, our team is at your service. We look forward to the opportunity to engage with you.

A: In a fiberglass core mat, the fiberglass is randomly oriented and loosely distributed in a three-dimensional structure. They are bonded together with a lightweight binder, which creates bulk and thickness while allowing easy resin flow and uniform impregnation throughout the laminate.

A: Yes, fiberglass core mat is compatible with polyester, vinyl ester, and epoxy resins. It is designed to allow easy resin penetration and wet-out with these common resin systems, making it suitable for a wide range of composite manufacturing processes and applications.

A: Fiberglass core mats differ from chopped strand mats mainly in structure and function. Core mats are designed to add thickness, stiffness, and bulk with minimal weight increase, utilizing a low-density, three-dimensional fiber structure that enables high resin absorption and enhanced laminate rigidity.

Chopped strand mats, by contrast, are denser and more compact, primarily used to provide reinforcement strength and bonding between layers rather than increasing laminate thickness.

A: Yes, fiberglass core mat can be customized to meet specific application requirements. Customization options typically include thickness, areal weight, width, roll length, binder type, and resin compatibility, allowing for tailoring to different laminate designs, manufacturing processes, and performance needs.

A: Fiberglass core mats have several limitations. They do not provide primary structural strength on their own and must be used in combination with reinforcing fabrics or mats. They also tend to absorb more resin, which can increase material cost and laminate weight if not properly designed. In addition, fiberglass core mats offer lower stiffness and load-bearing capacity compared to rigid core materials such as foam or balsa in highly structural applications.