Fiberglass Reinforced Plastic, widely known as FRP, is one of the most versatile composite materials used today. Over my years working with FRP, I have seen how its balance of strength, lightweight structure, and resistance to corrosion makes it the go-to solution for industries like construction, transportation, marine, and chemical processing. For buyers, understanding the FRP manufacturing process is essential to choosing the right product and ensuring long-term value.

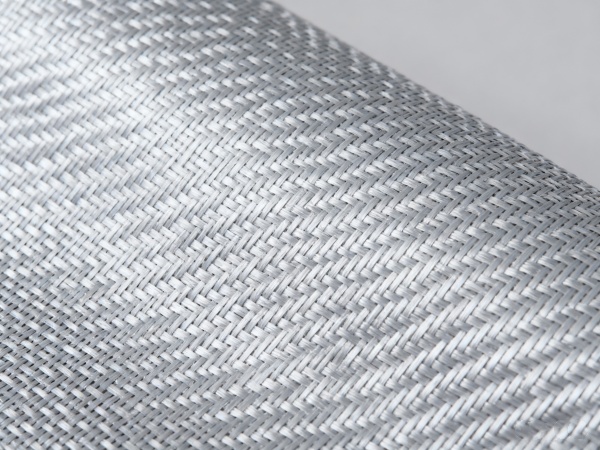

The two primary fiberglass reinforced plastic materials are fiberglass and resin. Fiberglass acts as the reinforcement, providing strength and rigidity, and comes in various forms such as chopped strand mat, woven roving, or continuous filament. Resin works as the matrix, binding the fibers together and protecting them from environmental damage.

Common resin types include:

Polyester resin – cost-effective and widely used.

Vinyl ester resin – excellent chemical and corrosion resistance.

Epoxy resin – superior bonding and mechanical strength.

Additives may also be included to enhance fire resistance, UV stability, or surface finish. The choice of raw materials in FRP production directly determines the durability, weight, and performance of the final product.

The core of the FRP manufacturing process lies in combining fiberglass layers with liquid resin. The fiberglass is laid into the mold, and resin is applied until the fibers are fully saturated. Once cured—either at room temperature or with added heat—the material forms a solid, high-strength composite.

When done properly, this process results in FRP that is lightweight yet incredibly strong. For example, in FRP storage tanks, carefully controlled resin-to-fiber ratios allow the structure to withstand both internal pressure and corrosive chemicals for years.

Different FRP production methods are used depending on the application:

1. Hand Lay-Up Method – economical and suitable for large, custom-built structures like boat hulls.

2. Pultrusion Process – continuous production for beams, rods, and pipes with consistent quality.

3. Compression Molding – used in automotive parts, offering uniform thickness and smooth finishes.

4. Filament Winding – perfect for cylindrical FRP products such as pipes and tanks, ensuring even strength distribution.

Buyers should note that the manufacturing technique greatly affects the product’s performance, cost, and suitability for specific applications.

Before reaching the customer, FRP products undergo quality testing to confirm strength and durability. Key tests include:

1. Tensile strength testing to measure load-bearing ability.

2. Flexural and impact testing to ensure resilience under stress.

3. Chemical resistance evaluation for products exposed to harsh environments.

Visual inspections are also performed to check for defects like air bubbles or cracks, which could weaken the final product. In my experience, suppliers with strict FRP quality control systems consistently deliver more reliable, cost-effective products to buyers.

For anyone new to FRP, it’s important to understand that this material is not simply fiberglass or resin alone—it is the result of a carefully engineered fiberglass reinforced plastic manufacturing process. From raw material selection to production methods and rigorous testing, each stage determines the performance and lifespan of the final product. Buyers who take time to understand these details are better positioned to select FRP solutions that meet both technical and budget requirements.