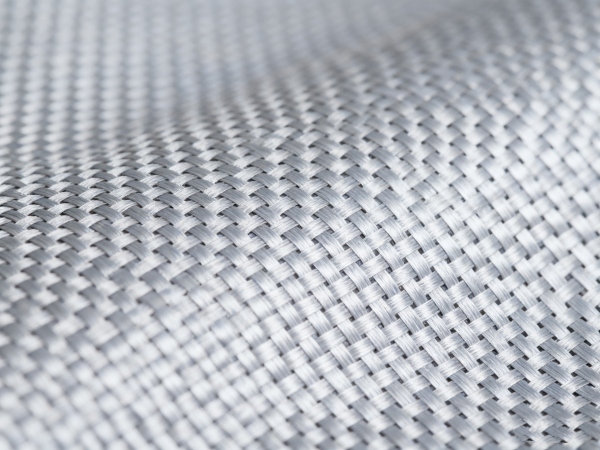

Yes, fiberglass reinforced plastics (FRP) are excellent materials for a wide range of applications. They offer high strength, lightweight properties, corrosion resistance, and low maintenance requirements, making them suitable for construction, industrial equipment, marine applications, and more. Their versatility and long-term durability make FRP a smart choice for buyers seeking reliable, cost-effective materials.

Yes. Fiberglass reinforced plastics (FRP) combine high-strength fibers with a polymer matrix, offering excellent durability and load-bearing capacity. They maintain structural integrity over time, making them ideal for construction, industrial equipment, and other demanding applications.

Absolutely. FRP does not rust or degrade like metal when exposed to moisture, acids, or alkalis. This makes it suitable for chemical plants, marine environments, and outdoor applications where corrosion resistance is essential.

Yes. FRP is much lighter than steel or aluminum while maintaining comparable strength. Its lightweight nature reduces transportation costs, simplifies installation, and allows for more versatile design options.

Yes. FRP is highly resistant to UV radiation, moisture, and temperature changes. It performs well in rain, snow, and intense sunlight without warping, cracking, or losing its mechanical properties.

Yes. FRP can be molded, cut, and drilled easily. Its adaptability makes it perfect for custom designs, retrofits, and projects that require unique shapes or sizes. Installation is generally faster than with traditional metal or concrete components.

Very little. Unlike metals that may require painting or rust prevention, FRP retains its durability and appearance over time. Occasional cleaning is usually sufficient, saving both labor and long-term costs.

Yes. While initial costs may be similar to metal or other composites, FRP’s long-term benefits—low maintenance, corrosion resistance, and durability—make it a highly cost-effective option for many industries.

FRP is used in construction, marine, automotive, aerospace, chemical processing, and water treatment. Its strength, corrosion resistance, and flexibility make it ideal for tanks, pipes, panels, and specialized equipment.

Traditional FRP is challenging to recycle, but advances in eco-friendly resins and recycling methods are improving sustainability. Many manufacturers now offer FRP products designed to reduce environmental impact.

You can purchase FRP from reputable industrial suppliers, distributors, or manufacturers with certified quality and technical support. When choosing a supplier, consider product specifications, durability, chemical resistance, and post-sale service to ensure the FRP meets your project needs.