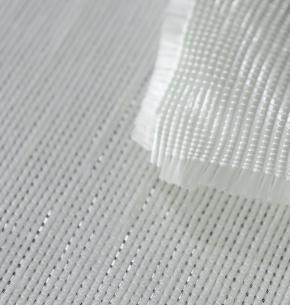

Multiaxial fabrics are a kind of multi-axis and multi-layered reinforcement. Layer count, orientation, weight, and fiber content of the layers vary based on product line and application via polyester yarn. Fabrics can be produced using multiple axis(0°, 90°, +45°, -45°), or combined with chopped mat layer. Mainly used for pultrusion, hand lay-up, filament winding, and RTM process, applied to wind energy, marine/ship building, recreation/leisure products, automotive, aerospace & defense, etc.

1. Increased strength, reduced product weight, and better surface finish

2. Orientated unidirectional layers are structurally more efficient

3. Quicker to wet-out than woven fabrics

4. Available in very heavy weights, allowing faster deposition rates

5. Binderless CSM can be added to further cut down on lay-up time and increase the speed of wet-out

If you have any questions, require additional information, or would like to contact our team, we are here to assist you.

Email: info@wtfiberglass.com

Phone: +86-573-88687898 / +86-18610855617

Address: No.168 Jianye Road, Fengming Street, Tongxiang, Zhejiang, China,314505

Website: https://www.wtfiberglass.com/

Should you have any questions regarding our products, production methods, or market insights, our team is at your service. We look forward to the opportunity to engage with you.

A: Multiaxial fabrics differ from woven fiberglass fabrics in that they are made by laying straight, non-crimped fibers in multiple orientations, such as 0°, 90°, and ±45°, and holding them together with stitching, which allows the fibers to carry loads more efficiently and improves strength and fatigue performance. Woven fiberglass fabrics, by contrast, interlace fibers over and under each other, introducing crimp that reduces mechanical efficiency but provides good dimensional stability and easier handling.

A: Fiberglass multiaxial fabrics are manufactured by laying continuous fiberglass rovings in specific orientations such as 0°, 90°, and ±45° in stacked layers, then mechanically stitching these layers together with a lightweight thread to hold the structure in place, without weaving or interlacing the fibers.

A: Yes, multiaxial fabrics are generally stronger than woven roving because their fibers remain straight and non-crimped, allowing loads to be carried more efficiently. This results in higher tensile and fatigue performance compared to woven roving of the same weight, where fiber crimp from weaving reduces mechanical efficiency.

A: Multiaxial fabrics commonly use fiber orientations of 0° for longitudinal strength, 90° for transverse reinforcement, and ±45° for shear and torsional load resistance, allowing the fabric to provide balanced, multidirectional structural performance.

A: Yes, multiaxial fabrics are generally easy to wet out because their fibers are straight and not tightly woven, allowing resin to flow freely between layers and fully impregnate the fabric during processes like hand lay-up, vacuum infusion, or resin transfer molding.